1. Retailers Guide to Long Draw Draft Beer Systems

2. Retailers Guide to Draft Beer Dispensing (Under 15 ft)

3. Home Draught Dispensing

Retailers Guide to Long Draw Draft Beer Systems

WHAT IS DRAFT BEER

Keg beer is almost never pasteurized; the result is much higher quality, brewery fresh beer. High temperatures will kill the flavor of the beer. Beer that has not been pasteurized must be stored cold and goes out of date much quicker than bottled beer (usually 45 days after the keg is filled).

To extend the shelf life, bottled beer is pasteurized at high temperatures.

Brewers and distributors take great care to keep kegs cold and get the kegs to the consumers as fast as is possible. It is also much cheaper per serving giving you the option to deliver better value to your customers.

Keg Specifications for U.S. 1/2 Barrel

Height of Keg -------------------------23.3 Inches

Diameter of Keg ---------------------16.0 - 17.0 Inches

Contents in Ounces ----------------1984.0 Ounces

Contents in Gallons -----------------15.5 Gallons

Contents in Liters --------------------58.7 Liters

Full Keg Weight ----------------------160.5 Pounds

Empty Keg Weight ------------------29.7 Pounds

Beer Weight ---------------------------130.8 Pounds

12 oz. Case Equivalent ------------6.8 Cases

12 oz Servings -----------------------165

16 oz. servings -----------------------124

Pouring beer

The bar staff must be properly trained to pour beer, clean and store glassware, and to recognize and report pouring problems. If the beer is pouring too fast, or is foamy, it cannot be fixed if it is not reported. Customers will let the server or bartender know if the beer does not taste right. Never pour from a system that is not working properly. You will waste beer and loose customers.

Glassware should be "beer clean". Beer glasses that are not cleaned using a detergent designed for beer glasses will cause both pouring and off taste problems. Petroleum based detergents used to clean other glassware and restaurant dishes leave a film on the glass that will cause co2 to break out of the beer. This results in foamy, flat tasting beer with little or no head retention. A beer served with no head on it does not look very appealing and is less profitable. Glassware chillers can also cause problems. Placing glassware in a cooler before it is allowed to dry after washing will not allow the sanitiser used in the final rinse to evaporate. This can give your beer an off taste. Freezing beer glasses should never be done for several reasons. Moisture will condensate on the inside of the glass when it is removed from the freezer even if it is put away dry. This will water down the beer. This also creates a layer of ice inside of the glass that will cause a lot of foam and waste driving up the beer cost. Most beers were intended to be served between 38 and 50 degrees. Serving the beer too cold will numb the customer's palate and remove much of the beer's flavor. It is easy to spot a glass that is not beer clean. Bubbles in the beer will cling to the inside of the glass and there will be large bubbles in the head. Beer served in a beer clean glass will have no bubbles clinging to the inside of the glass and have a tight head with small bubbles.

2. Retailers Guide to Draft Beer Dispensing (Under 15 ft)

3. Home Draught Dispensing

Retailers Guide to Long Draw Draft Beer Systems

WHAT IS DRAFT BEER

Keg beer is almost never pasteurized; the result is much higher quality, brewery fresh beer. High temperatures will kill the flavor of the beer. Beer that has not been pasteurized must be stored cold and goes out of date much quicker than bottled beer (usually 45 days after the keg is filled).

To extend the shelf life, bottled beer is pasteurized at high temperatures.

Brewers and distributors take great care to keep kegs cold and get the kegs to the consumers as fast as is possible. It is also much cheaper per serving giving you the option to deliver better value to your customers.

Keg Specifications for U.S. 1/2 Barrel

Height of Keg -------------------------23.3 Inches

Diameter of Keg ---------------------16.0 - 17.0 Inches

Contents in Ounces ----------------1984.0 Ounces

Contents in Gallons -----------------15.5 Gallons

Contents in Liters --------------------58.7 Liters

Full Keg Weight ----------------------160.5 Pounds

Empty Keg Weight ------------------29.7 Pounds

Beer Weight ---------------------------130.8 Pounds

12 oz. Case Equivalent ------------6.8 Cases

12 oz Servings -----------------------165

16 oz. servings -----------------------124

Pouring beer

The bar staff must be properly trained to pour beer, clean and store glassware, and to recognize and report pouring problems. If the beer is pouring too fast, or is foamy, it cannot be fixed if it is not reported. Customers will let the server or bartender know if the beer does not taste right. Never pour from a system that is not working properly. You will waste beer and loose customers.

Glassware should be "beer clean". Beer glasses that are not cleaned using a detergent designed for beer glasses will cause both pouring and off taste problems. Petroleum based detergents used to clean other glassware and restaurant dishes leave a film on the glass that will cause co2 to break out of the beer. This results in foamy, flat tasting beer with little or no head retention. A beer served with no head on it does not look very appealing and is less profitable. Glassware chillers can also cause problems. Placing glassware in a cooler before it is allowed to dry after washing will not allow the sanitiser used in the final rinse to evaporate. This can give your beer an off taste. Freezing beer glasses should never be done for several reasons. Moisture will condensate on the inside of the glass when it is removed from the freezer even if it is put away dry. This will water down the beer. This also creates a layer of ice inside of the glass that will cause a lot of foam and waste driving up the beer cost. Most beers were intended to be served between 38 and 50 degrees. Serving the beer too cold will numb the customer's palate and remove much of the beer's flavor. It is easy to spot a glass that is not beer clean. Bubbles in the beer will cling to the inside of the glass and there will be large bubbles in the head. Beer served in a beer clean glass will have no bubbles clinging to the inside of the glass and have a tight head with small bubbles.

All About Beer - Draft Beer Technology

Welcome to the page about draft beer technology. There is some usefull information information, from kegerator, homebar, small bar to biggest installations with 50 or mere beers.

We produce a lot of different custom draft beer towers, from single faucet kegerator tower to huge 17' long and 14' tall .

We produce a lot of different custom draft beer towers, from single faucet kegerator tower to huge 17' long and 14' tall .

DRAFT SYSTEMS

Air Cooled System

In the not so distant past most all draft beer was stored under the bar in a large keg cooler. In these simple draft systems beer travels through a short line, about six-foot long, that runs up an air-cooled three-inch tube to a faucet. This is always the prefered way to dispense beer and works well if you sell only one or two brands of beer, allowing room behind your bar to store all of your kegs. Unfortunately if you have six different brands on tap and a back up for each, twelve kegs behind the bar tends to get in the way. Wheeling a 160-pound keg from the back cooler through a busy kitchen and restaurant at 7:30 on a Friday night isn't much better. The only solution is to run the beer lines from a remote location to the bar. This is referred to as a closed remote draft system, usually a glycol system.

GLYCOL DRAFT SYSTEMS

Draft beer must be kept less than 42 degrees from the tap all the way to the faucet. If the beer is not kept cold all the way to the faucet the quality of the beer will suffer greatly. Glycol draft systems allow you to keep the beer cold even if the lines are very long.

Glycol systems have five major parts. One, a cooler large enough to store all of your kegs. Two, an insulated trunk line that the beer runs through after it leaves the storage cooler. Three, a power pack that refrigerates the trunk line. Four, the gas system that maintains the beer's natural carbonation and pushes the beer to the faucet. And five, the draft tower mounted proudly on the bar.

Glycol systems work perfectly and waste very little beer if they are designed, installed, maintained, and used properly. Unfortunately most glycol systems fall short in one of these four areas.

If the system is not designed properly using all of the needed components it will waste beer and your bartenders time by producing excessive foam. A draft system is like a car. There are many parts on a car that are not needed to make it run smoothly. But I wouldn't buy a car that did not have a gas gauge no matter how well it ran. If you are cutting costs on a draft system make sure they are cosmetic. Do not remove options that make the system work better.

Make sure your installer has done good work in the past. Get references to insure your system is professionally installed. Ask lots of questions. There are no stupid questions. Go see an example of his or her work if possible. A glycol system is a big investment that will return large profits if installed properly.

All draft systems, especially those with long lines, must have preventative maintenance service at least every two weeks. At the very least the lines should be cleaned and the faucet should be removed and cleaned. The lines cleaner should also check the temperature of the beer that is in the lines and the temperature of the storage area during every cleaning. This will help weed out many problems before they become beer wasters.

USING CO2 TO DISPENSE BEER

You should never adjust the beer's guage pressure to control the flow rate of the beer. The flow rate is controled by adjusting the length of the beer line.

The gas system is a very important part of any draft beer system. When a draft system has very long lines it can mean the difference between a perfect system and one that you regret purchasing. The gas system can easily effect both the taste of the beer and how easy (or difficult) your draft system is to pour from. All beers have some CO2 gas dissolved in them. American lagers have a lot, many micros and imports have very little. The dissolved gas level of the beer effects the "nose" of the beer and also the way it feels and tastes in your mouth. A few beers that are served almost flat (Guinness is one example) also have nitrogen gas dissolved in them so they will still have a head on them.

When you are using CO2 to dispense beer the beer is sensitive to picking up too much gas (over carbonation), and also loosing gas (going flat). Whatever gas you are using, it always comes into contact with the beer in the keg. The gas entering the keg pushes down on the beer forcing it up a tube and out into the draft system. When using 100% CO2 there is very little room for error when deciding how much pressure is needed in the keg. If the temperature of the beer raises 2 degrees F one more pound of pressure is needed. If the temperature of the beer drops 2 degrees the pressure in the keg needs to be reduced by one pound. Different brands of beer also need different amounts of pressure. For example at 36 degrees, Coors needs 15psi, Budweiser needs 12psi, Killians Lager needs 13psi, and Bass Ale needs 9psi. If the pressure is more than 2psi out of calibration the carbonation level of the beer will change causing off taste, pouring problems, or both.

In summary, if the right qualified individual adjusts the CO2 pressure for each beer properly, and if the temperature of the beer never changes more than plus or minus 4 degrees, using CO2 is O.K.. In reality I do not recommend using plain CO2 to dispense beer, especially with long lines. There are too many things that can and will go wrong. Beer is far too expensive to waste.

Air Cooled System

In the not so distant past most all draft beer was stored under the bar in a large keg cooler. In these simple draft systems beer travels through a short line, about six-foot long, that runs up an air-cooled three-inch tube to a faucet. This is always the prefered way to dispense beer and works well if you sell only one or two brands of beer, allowing room behind your bar to store all of your kegs. Unfortunately if you have six different brands on tap and a back up for each, twelve kegs behind the bar tends to get in the way. Wheeling a 160-pound keg from the back cooler through a busy kitchen and restaurant at 7:30 on a Friday night isn't much better. The only solution is to run the beer lines from a remote location to the bar. This is referred to as a closed remote draft system, usually a glycol system.

GLYCOL DRAFT SYSTEMS

Draft beer must be kept less than 42 degrees from the tap all the way to the faucet. If the beer is not kept cold all the way to the faucet the quality of the beer will suffer greatly. Glycol draft systems allow you to keep the beer cold even if the lines are very long.

Glycol systems have five major parts. One, a cooler large enough to store all of your kegs. Two, an insulated trunk line that the beer runs through after it leaves the storage cooler. Three, a power pack that refrigerates the trunk line. Four, the gas system that maintains the beer's natural carbonation and pushes the beer to the faucet. And five, the draft tower mounted proudly on the bar.

Glycol systems work perfectly and waste very little beer if they are designed, installed, maintained, and used properly. Unfortunately most glycol systems fall short in one of these four areas.

If the system is not designed properly using all of the needed components it will waste beer and your bartenders time by producing excessive foam. A draft system is like a car. There are many parts on a car that are not needed to make it run smoothly. But I wouldn't buy a car that did not have a gas gauge no matter how well it ran. If you are cutting costs on a draft system make sure they are cosmetic. Do not remove options that make the system work better.

Make sure your installer has done good work in the past. Get references to insure your system is professionally installed. Ask lots of questions. There are no stupid questions. Go see an example of his or her work if possible. A glycol system is a big investment that will return large profits if installed properly.

All draft systems, especially those with long lines, must have preventative maintenance service at least every two weeks. At the very least the lines should be cleaned and the faucet should be removed and cleaned. The lines cleaner should also check the temperature of the beer that is in the lines and the temperature of the storage area during every cleaning. This will help weed out many problems before they become beer wasters.

USING CO2 TO DISPENSE BEER

You should never adjust the beer's guage pressure to control the flow rate of the beer. The flow rate is controled by adjusting the length of the beer line.

The gas system is a very important part of any draft beer system. When a draft system has very long lines it can mean the difference between a perfect system and one that you regret purchasing. The gas system can easily effect both the taste of the beer and how easy (or difficult) your draft system is to pour from. All beers have some CO2 gas dissolved in them. American lagers have a lot, many micros and imports have very little. The dissolved gas level of the beer effects the "nose" of the beer and also the way it feels and tastes in your mouth. A few beers that are served almost flat (Guinness is one example) also have nitrogen gas dissolved in them so they will still have a head on them.

When you are using CO2 to dispense beer the beer is sensitive to picking up too much gas (over carbonation), and also loosing gas (going flat). Whatever gas you are using, it always comes into contact with the beer in the keg. The gas entering the keg pushes down on the beer forcing it up a tube and out into the draft system. When using 100% CO2 there is very little room for error when deciding how much pressure is needed in the keg. If the temperature of the beer raises 2 degrees F one more pound of pressure is needed. If the temperature of the beer drops 2 degrees the pressure in the keg needs to be reduced by one pound. Different brands of beer also need different amounts of pressure. For example at 36 degrees, Coors needs 15psi, Budweiser needs 12psi, Killians Lager needs 13psi, and Bass Ale needs 9psi. If the pressure is more than 2psi out of calibration the carbonation level of the beer will change causing off taste, pouring problems, or both.

In summary, if the right qualified individual adjusts the CO2 pressure for each beer properly, and if the temperature of the beer never changes more than plus or minus 4 degrees, using CO2 is O.K.. In reality I do not recommend using plain CO2 to dispense beer, especially with long lines. There are too many things that can and will go wrong. Beer is far too expensive to waste.

USING BLENDED GAS (BEER GAS) TO DISPENSE BEER

Beer gas is a very simple and very effective way to solve most draft problems. If the temperature in your beer storage area does not remain constant due to high traffic. Or if your trunk line is not at least as cold as your cooler forcing you to raise your pressure above ideal, a blend will prevent over carbonation. Beer gas will many times allow you to run all of your beers at the same pressure solving problems caused by different beers flowing at different rates.

Add Nitrogen advantage

BEER GAS DON'TS

As with anything else there is a wrong way and a right way to use beer gas. If you do not use the proper equipment beer gas can damage the beer and also be very expensive.

PRE-MIXED VS ON SITE BLENDING

Beer gas is available one of two ways. You can purchase beer gas already blended in a CO2 bottle, or you can purchase a blender and make your own beer gas on site.

Pre-mixed beer gas (sometimes called aligal) is an option if you cannot afford to purchase a blender. There are two drawbacks to using pre-mixed gas. First, it is much more expensive over time than an on site blender. Pre-mixed gas is about three times as expensive as buying nitrogen and CO2 to mix on site. Second, there are few choices in blends when you buy pre-mixed. The available blends are usually very low in co2 and are not right for everyone. Too little co2 in the blend will cause the beer to loose it's natural carbonation and go flat over time. Serving flat beer with no head can have a greater negative effect on your beer cost than foaming problems caused by over carbonation using pure co2.

Blending Gases On Site

The only drawback to using a good blender is the up front purchase price. A reliable blender ranges in price from about $450 - $700. There are also plenty of mistakes that can be made.

Some really cheap blenders such as the one pictured above will work even if they are out of one of the gasses. For example, if your nitrogen bottle is empty these blenders will dispense all CO2 causing severe over carbonation. Cheap blenders are also easy to adjust on site. This creates problems with the wrong people making adjustments that will cause damage to the beer. Once the correct blend is selected and the system is set up no further adjustment is necessary.

Do not use AIR COMPRESSORS

Some draft parts vendors also offer blenders that mix the CO2 with compressed air to save money on nitrogen. Compressed air will make your beer smell and taste bad in a very short period of time. I cannot emphasize this enough; AIR COMPRESSORS WILL RUIN YOUR BEER AND CHASE AWAY YOUR CUSTOMERS. A 240 cubic foot bottle of nitrogen costs between $15 and $30 and will dispense about 80 kegs.

I recommend using the McDantim Trumix-100 gas blender (or Trumix-200 if you sell a nitrogenated beer like Guinness). Many draft equipment suppliers sell it as a private label product. It is very accurate under a wide range of flow demands, has no moving parts to wear out, will not operate if one of the gas supplies has run out, and is tamper proof. The blender from Johnson Enterprises pictured below is a McDantim blender set up to produce two blends. One side is 55% co2 and 45% Nitrogen. This is for the ordinary beers being dispensed at 25 psi. The other side is 25% co2 and 75% nitrogen for Guinness.

¸

Beer gas is a very simple and very effective way to solve most draft problems. If the temperature in your beer storage area does not remain constant due to high traffic. Or if your trunk line is not at least as cold as your cooler forcing you to raise your pressure above ideal, a blend will prevent over carbonation. Beer gas will many times allow you to run all of your beers at the same pressure solving problems caused by different beers flowing at different rates.

Add Nitrogen advantage

BEER GAS DON'TS

As with anything else there is a wrong way and a right way to use beer gas. If you do not use the proper equipment beer gas can damage the beer and also be very expensive.

PRE-MIXED VS ON SITE BLENDING

Beer gas is available one of two ways. You can purchase beer gas already blended in a CO2 bottle, or you can purchase a blender and make your own beer gas on site.

Pre-mixed beer gas (sometimes called aligal) is an option if you cannot afford to purchase a blender. There are two drawbacks to using pre-mixed gas. First, it is much more expensive over time than an on site blender. Pre-mixed gas is about three times as expensive as buying nitrogen and CO2 to mix on site. Second, there are few choices in blends when you buy pre-mixed. The available blends are usually very low in co2 and are not right for everyone. Too little co2 in the blend will cause the beer to loose it's natural carbonation and go flat over time. Serving flat beer with no head can have a greater negative effect on your beer cost than foaming problems caused by over carbonation using pure co2.

Blending Gases On Site

The only drawback to using a good blender is the up front purchase price. A reliable blender ranges in price from about $450 - $700. There are also plenty of mistakes that can be made.

Some really cheap blenders such as the one pictured above will work even if they are out of one of the gasses. For example, if your nitrogen bottle is empty these blenders will dispense all CO2 causing severe over carbonation. Cheap blenders are also easy to adjust on site. This creates problems with the wrong people making adjustments that will cause damage to the beer. Once the correct blend is selected and the system is set up no further adjustment is necessary.

Do not use AIR COMPRESSORS

Some draft parts vendors also offer blenders that mix the CO2 with compressed air to save money on nitrogen. Compressed air will make your beer smell and taste bad in a very short period of time. I cannot emphasize this enough; AIR COMPRESSORS WILL RUIN YOUR BEER AND CHASE AWAY YOUR CUSTOMERS. A 240 cubic foot bottle of nitrogen costs between $15 and $30 and will dispense about 80 kegs.

I recommend using the McDantim Trumix-100 gas blender (or Trumix-200 if you sell a nitrogenated beer like Guinness). Many draft equipment suppliers sell it as a private label product. It is very accurate under a wide range of flow demands, has no moving parts to wear out, will not operate if one of the gas supplies has run out, and is tamper proof. The blender from Johnson Enterprises pictured below is a McDantim blender set up to produce two blends. One side is 55% co2 and 45% Nitrogen. This is for the ordinary beers being dispensed at 25 psi. The other side is 25% co2 and 75% nitrogen for Guinness.

¸

FLOW OF BEER (F.O.B.) STOPS

a.k.a. Draft Foam Control (D.F.C.)

There is very little to say about these. They simply shut off the beer flow at the keg when it is empty preventing the lines from draining. This will save the as much as one gallon of beer you would otherwise waste trying to pack the lines every time you change a keg.

1.) Step one illustrates normal operation. Beer enters the side and exits through the bottom. The red check ball floats on top of the beer.

2.) Step two shows the keg is empty and is filling the FOB stop with air from the empty keg.

3.) Step three shows that as the fob stop emptied the check ball prevented the air from entering the main beer line.

When the bartender is pouring beer and the keg goes empty the beer simply stops flowing from the faucet. The bartender changes the keg in the normal way then opens the vent on the top of the FOB (shown in blue). The vent lets the beer enter the FOB from the new keg. Once the fob is full of beer (about two seconds later) the check ball floats to the top and allows the beer to flow normally. There is no need to let the beer run down the drain for sixty seconds, as you would without the FOB stop.

PUMPS

Beer pumps solve most of the same problems as blended gas. Beer pumps apply mechanical pressure to the beer in the trunk line instead of using the pressure in the line coming from the keg. This eliminates problems caused by beer in the trunk line being warmer than the beer in the cooler, which results in either over carbonation or beer going flat in the lines. They also prevent beers set at different amounts of pressure from flowing at different rates. Pumps allow you to avoid these problems without buying any gas other than CO2, which is much cheaper over time.

They will not prevent over carbonation problems caused by temperature changes in the storage cooler. Because of this I recommend using this method only if your cooler is for beer storage only and the kegs on line are always kept at the same temperature. Pumps should not be used in high traffic or unreliable coolers without blended gas.

AVOIDING PROBLEMS

All draft systems must have preventative maintenance service at least every two weeks. At the very least the lines should be cleaned and the faucet should be removed and cleaned. The lines cleaner should also check the temperature of the beer during every cleaning. This will help weed out many problems before they become beer wasters.

Pouring problems result when beer goes flat - too low pressure or a keg is exposed to too much pressure for too long. These problems can be cured by having enough secondary regulators to run each beer at it's ideal gauge pressure and being careful to store the beer at an even temperature.

a.k.a. Draft Foam Control (D.F.C.)

There is very little to say about these. They simply shut off the beer flow at the keg when it is empty preventing the lines from draining. This will save the as much as one gallon of beer you would otherwise waste trying to pack the lines every time you change a keg.

1.) Step one illustrates normal operation. Beer enters the side and exits through the bottom. The red check ball floats on top of the beer.

2.) Step two shows the keg is empty and is filling the FOB stop with air from the empty keg.

3.) Step three shows that as the fob stop emptied the check ball prevented the air from entering the main beer line.

When the bartender is pouring beer and the keg goes empty the beer simply stops flowing from the faucet. The bartender changes the keg in the normal way then opens the vent on the top of the FOB (shown in blue). The vent lets the beer enter the FOB from the new keg. Once the fob is full of beer (about two seconds later) the check ball floats to the top and allows the beer to flow normally. There is no need to let the beer run down the drain for sixty seconds, as you would without the FOB stop.

PUMPS

Beer pumps solve most of the same problems as blended gas. Beer pumps apply mechanical pressure to the beer in the trunk line instead of using the pressure in the line coming from the keg. This eliminates problems caused by beer in the trunk line being warmer than the beer in the cooler, which results in either over carbonation or beer going flat in the lines. They also prevent beers set at different amounts of pressure from flowing at different rates. Pumps allow you to avoid these problems without buying any gas other than CO2, which is much cheaper over time.

They will not prevent over carbonation problems caused by temperature changes in the storage cooler. Because of this I recommend using this method only if your cooler is for beer storage only and the kegs on line are always kept at the same temperature. Pumps should not be used in high traffic or unreliable coolers without blended gas.

AVOIDING PROBLEMS

All draft systems must have preventative maintenance service at least every two weeks. At the very least the lines should be cleaned and the faucet should be removed and cleaned. The lines cleaner should also check the temperature of the beer during every cleaning. This will help weed out many problems before they become beer wasters.

Pouring problems result when beer goes flat - too low pressure or a keg is exposed to too much pressure for too long. These problems can be cured by having enough secondary regulators to run each beer at it's ideal gauge pressure and being careful to store the beer at an even temperature.

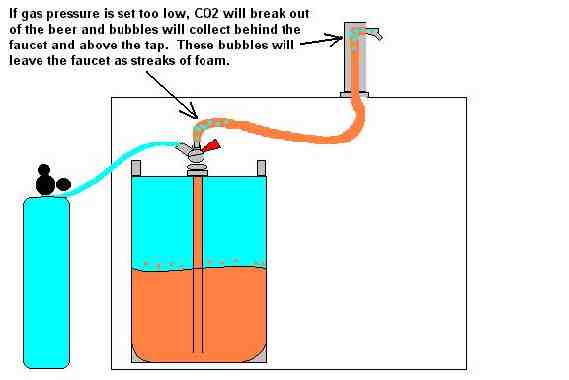

Low pressure

If your beer is going flat while in the lines it is caused by the pressure being set too low. It will be obvious to you because the beer line will collect pockets of CO2 gas.

These pockets of gas will be worse the longer you go between uses of the tap. They will also be worse when the keg has a lot of beer in it because as the gas breaks out of the beer, it will eventually become flat enough that the problem will stop. You will usually experience this problem during at least first half of the keg.

The pockets of gas collect right above the keg and directly behind the faucet, therefore when you open the faucet you will get a shot of foam, about 4 ounces of clear beer, followed by another shot of foam. After which the beer will pour clear until the tap is at rest for 10 minutes or so, allowing the gas pockets to build up again. Remember that as the temperature of the beer increases, it will require more pressure so these same symptoms will occur if the cooler or beer is more than 4 degrees higher than what the pressure was set for. This is why it is important to keep the beer at a constant temperature. Whether you are using a keg box or a walk in cooler it is important to keep the door closed so that the keg temperature does not fluctuate. If you are using a keg box it is not wise to store garnishes, tomato juice, or liquor bottles in the cooler that would require you to open the door frequently. Gas will also break out of the beer behind the faucet if the dispense tower is not cooled properly. There should be some sort of way set up to force cool air into the tower. If the tower is not cooled properly it can also cause the section of line in the tower to build up a lot of yeast growth. No matter how often you have your beer lines cleaned this build up due to warm lines will cause problems with off taste product.

These pockets of gas will be worse the longer you go between uses of the tap. They will also be worse when the keg has a lot of beer in it because as the gas breaks out of the beer, it will eventually become flat enough that the problem will stop. You will usually experience this problem during at least first half of the keg.

The pockets of gas collect right above the keg and directly behind the faucet, therefore when you open the faucet you will get a shot of foam, about 4 ounces of clear beer, followed by another shot of foam. After which the beer will pour clear until the tap is at rest for 10 minutes or so, allowing the gas pockets to build up again. Remember that as the temperature of the beer increases, it will require more pressure so these same symptoms will occur if the cooler or beer is more than 4 degrees higher than what the pressure was set for. This is why it is important to keep the beer at a constant temperature. Whether you are using a keg box or a walk in cooler it is important to keep the door closed so that the keg temperature does not fluctuate. If you are using a keg box it is not wise to store garnishes, tomato juice, or liquor bottles in the cooler that would require you to open the door frequently. Gas will also break out of the beer behind the faucet if the dispense tower is not cooled properly. There should be some sort of way set up to force cool air into the tower. If the tower is not cooled properly it can also cause the section of line in the tower to build up a lot of yeast growth. No matter how often you have your beer lines cleaned this build up due to warm lines will cause problems with off taste product.

High pressure

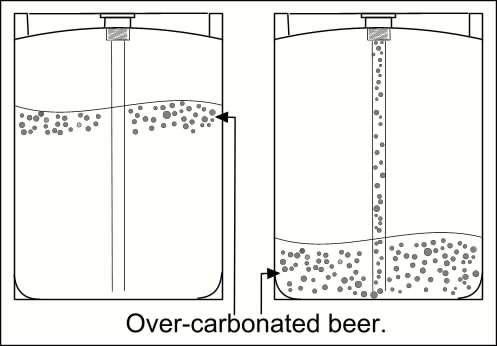

If your keg is exposed to too much pressure or is on line for too long you will experience problems caused by over carbonation. Over carbonation symptoms appear when the carbonation level of the beer increases because the pressure is set too high.

Mild over carbonation symptoms usually closely resemble those caused by beer going flat in the lines. The difference is that they will appear when the keg is nearly empty (the last 1/3 or so). Remember that as the temperature of the beer drops, it needs less pressure to maintain the proper carbonation level. Therefore, you may see these problems if your beer is stored on line at temperatures less than 35 degrees. The ideal temperature range for keg storage is 35 to 40 degrees.

( I receive a lot of email about this claiming 40 degrees is too cold. I recommend you never allow your draft beer to get warmer than 43 degrees F at any point in the system because the beer is more protected from spoilage and oxidation. If you like your beer warmer than this, rinse your glass with warm water before pouring and keep the keg stored at 35 - 40 degrees.)

Beer in direct contact with the gas picks up the CO2 first. It takes a lot of time for the gas to absorb deeply into the beer so over carbonation usually is most evident at the end of the keg. If you tap a fresh keg and it is very foamy, there is a 99.9% chance that the problem is not over carbonation.

Mild over carbonation symptoms usually closely resemble those caused by beer going flat in the lines. The difference is that they will appear when the keg is nearly empty (the last 1/3 or so). Remember that as the temperature of the beer drops, it needs less pressure to maintain the proper carbonation level. Therefore, you may see these problems if your beer is stored on line at temperatures less than 35 degrees. The ideal temperature range for keg storage is 35 to 40 degrees.

( I receive a lot of email about this claiming 40 degrees is too cold. I recommend you never allow your draft beer to get warmer than 43 degrees F at any point in the system because the beer is more protected from spoilage and oxidation. If you like your beer warmer than this, rinse your glass with warm water before pouring and keep the keg stored at 35 - 40 degrees.)

Beer in direct contact with the gas picks up the CO2 first. It takes a lot of time for the gas to absorb deeply into the beer so over carbonation usually is most evident at the end of the keg. If you tap a fresh keg and it is very foamy, there is a 99.9% chance that the problem is not over carbonation.

Home Draught Dispensing

CO2

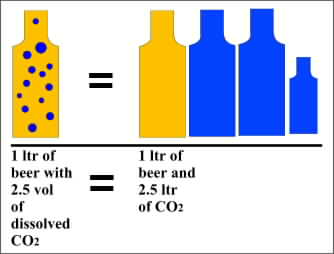

The first thing you need to understand is carbonation. CO2 is a gas that dissolves easily into water (and beer). The amount of gas dissolved into beer is measured in volumes. If one liter of beer is carbonated to 2.5 volumes, then there are 2.5 liters of CO2 gas dissolved into the beer.

The first thing you need to understand is carbonation. CO2 is a gas that dissolves easily into water (and beer). The amount of gas dissolved into beer is measured in volumes. If one liter of beer is carbonated to 2.5 volumes, then there are 2.5 liters of CO2 gas dissolved into the beer.

CO2 gas has little or no detectable flavor, but as gas comes out of the solution (bubbles and foam), it does release aromas and flavor characteristics in the beer, affecting the flavor. When a brewer produces a beer, he takes care to control the carbonation level in a way to bring out the flavors and aroma, to effect the flavor in a controlled way. Usually, beers with a strong bitterness and aroma are not carbonated as highly as beers with less flavor and aroma.

For example, Bass Ale is carbonated to 2.2 volumes of CO2. Bass has a fruity sweet flavor and a decent amount of bitterness and aroma from hops. A relatively low CO2 level of 2.2 volumes compliments it perfectly. It makes the beer feel smooth in the mouth and releases just the right amount of the complex hop and malt aroma.

On the other hand, Coors Light has 2.8 volumes of dissolved CO2 (from Golden, CO brewery). Coors light is not very malty or "hoppy", therefore it has more CO2 to help bring out the "qualities" it does have.

Pressure

Pressure, measured in pounds per square inch, is defined as the force at which the CO2 molecules in the head space of the keg push on the beer. As the pressure increases, the gas hits the beer with more force and dissolves into the beer more easily. As the pressure decreases, the gas does not dissolve into the beer as easily and gas can come out of the beer.

High pressure increases the carbonation level, low pressure reduces the carbonation level. The right amount of pressure in a keg will maintain the right carbonation level.

Most breweries or distributors can give you suggested pressure settings for the beers they sell. If you make your own beer use a carbonation chart to determine the proper pressure.

Temperature and CO2 Balance

The temperature of the beer effects the amount of pressure needed in the keg to control the carbonation level. As temperature increases, CO2 bubbles expand and will come out of the beer. As temperature drops, CO2 dissolves more easily into the beer.

For example, at 38 degrees F, Coors Light needs 15 psi to maintain its CO2 level. At 40 deg F it needs 16 psi. At 36 deg F it needs 14 psi.

Generally, a two degree increase in temperature requires a one pound increase in pressure. A two degree decrease in temperature requires a one pound decrease in pressure.

For example, Bass Ale is carbonated to 2.2 volumes of CO2. Bass has a fruity sweet flavor and a decent amount of bitterness and aroma from hops. A relatively low CO2 level of 2.2 volumes compliments it perfectly. It makes the beer feel smooth in the mouth and releases just the right amount of the complex hop and malt aroma.

On the other hand, Coors Light has 2.8 volumes of dissolved CO2 (from Golden, CO brewery). Coors light is not very malty or "hoppy", therefore it has more CO2 to help bring out the "qualities" it does have.

Pressure

Pressure, measured in pounds per square inch, is defined as the force at which the CO2 molecules in the head space of the keg push on the beer. As the pressure increases, the gas hits the beer with more force and dissolves into the beer more easily. As the pressure decreases, the gas does not dissolve into the beer as easily and gas can come out of the beer.

High pressure increases the carbonation level, low pressure reduces the carbonation level. The right amount of pressure in a keg will maintain the right carbonation level.

Most breweries or distributors can give you suggested pressure settings for the beers they sell. If you make your own beer use a carbonation chart to determine the proper pressure.

Temperature and CO2 Balance

The temperature of the beer effects the amount of pressure needed in the keg to control the carbonation level. As temperature increases, CO2 bubbles expand and will come out of the beer. As temperature drops, CO2 dissolves more easily into the beer.

For example, at 38 degrees F, Coors Light needs 15 psi to maintain its CO2 level. At 40 deg F it needs 16 psi. At 36 deg F it needs 14 psi.

Generally, a two degree increase in temperature requires a one pound increase in pressure. A two degree decrease in temperature requires a one pound decrease in pressure.

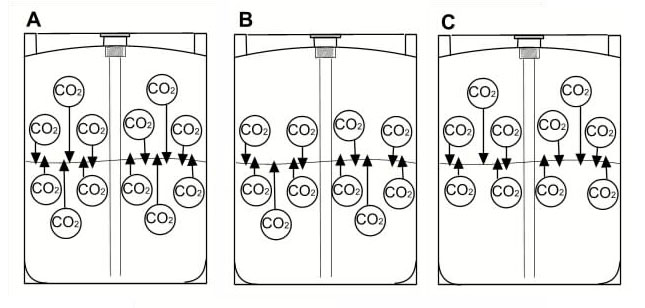

Illustration "A" represents CO2 pressure adjusted properly for the storage temperature and carbonation level of the beer. There is an equal amount of CO2 dissolving into and breaking out of the beer.

Illustration "B" represents too little CO2 pressure. Gas breaks out of the beer into the head space of the keg and in the lines. Pockets of gas will accumulate in the lines creating pouring problems as well as flat tasting beer.

Illustration "C" represents too much CO2 pressure, more CO2 is dissolving into the beer than is breaking out. The carbonation level of the beer is increasing. Pouring problems and "buzzy" tasting beer will result when the keg is low and dispenses the over carbonated beer. Over carbonated is often perceived as tasting extra bitter.

Pouring Problems and CO2

Pouring problems result when beer goes flat while in the lines or a keg is exposed to too much pressure for too long. These problems can be cured by having enough secondary regulators to run each beer at it's ideal gauge pressure and being careful to store the beer at an even temperature.

Maintaining Quality

Five things must be done to maintain the quality of the beer being dispensed.

The first is to prevent oxygen from entering the keg. If your keg is going to last more than two days you must use CO2 to pressurize the keg. Hand pumps are not OK for anything other than one night long parties. 'Nuf said.

Second, the beer must be consumed in a reasonable amount of time. Draft beer is generally only good for 45 days after it is filled. Don't buy a keg to save money if you cannot consume it in a reasonable amount of time, you will be doing yourself a favor to only buy as much beer as you can consume in a week, two at the most. 1/4 bbls and 1/6 bbls can be a good solution to this.

Third, the beer must be kept cold. The 45 day expiration date usually assumes the beer will be kept below 40 deg F. Higher temperatures greatly accelerate spoilage. The entire system must be kept cold, from the keg to the faucet. A good rule is to treat beer the same way you would treat milk.

Fourth, the system should be cleaned after every keg or every two weeks, which ever is longer. Line cleaning kits for home systems are available and usually cost under $50 - $80.

Fifth, you must keep the glassware in very good condition. If you do not use cleaner designed for bar glasses then beer glasses should be cleaned especially well and rinsed very well. Always allow them to air dry, do not towel dry. If (god forbid) you freeze your glasses, don't put them in the freezer 'til they're dry. Freezing your glassware will destroy the beer's flavor and cause a lot of foam.

Illustration "B" represents too little CO2 pressure. Gas breaks out of the beer into the head space of the keg and in the lines. Pockets of gas will accumulate in the lines creating pouring problems as well as flat tasting beer.

Illustration "C" represents too much CO2 pressure, more CO2 is dissolving into the beer than is breaking out. The carbonation level of the beer is increasing. Pouring problems and "buzzy" tasting beer will result when the keg is low and dispenses the over carbonated beer. Over carbonated is often perceived as tasting extra bitter.

Pouring Problems and CO2

Pouring problems result when beer goes flat while in the lines or a keg is exposed to too much pressure for too long. These problems can be cured by having enough secondary regulators to run each beer at it's ideal gauge pressure and being careful to store the beer at an even temperature.

Maintaining Quality

Five things must be done to maintain the quality of the beer being dispensed.

The first is to prevent oxygen from entering the keg. If your keg is going to last more than two days you must use CO2 to pressurize the keg. Hand pumps are not OK for anything other than one night long parties. 'Nuf said.

Second, the beer must be consumed in a reasonable amount of time. Draft beer is generally only good for 45 days after it is filled. Don't buy a keg to save money if you cannot consume it in a reasonable amount of time, you will be doing yourself a favor to only buy as much beer as you can consume in a week, two at the most. 1/4 bbls and 1/6 bbls can be a good solution to this.

Third, the beer must be kept cold. The 45 day expiration date usually assumes the beer will be kept below 40 deg F. Higher temperatures greatly accelerate spoilage. The entire system must be kept cold, from the keg to the faucet. A good rule is to treat beer the same way you would treat milk.

Fourth, the system should be cleaned after every keg or every two weeks, which ever is longer. Line cleaning kits for home systems are available and usually cost under $50 - $80.

Fifth, you must keep the glassware in very good condition. If you do not use cleaner designed for bar glasses then beer glasses should be cleaned especially well and rinsed very well. Always allow them to air dry, do not towel dry. If (god forbid) you freeze your glasses, don't put them in the freezer 'til they're dry. Freezing your glassware will destroy the beer's flavor and cause a lot of foam.

Pressure Regulators

There are many brands of pressure regulators. The prices vary greatly, all are basically the same. There are a few features that are important to look for.

There should be secondary a pressure gauge that reads, at most, 60 psi. Gauges that read higher than this are difficult to adjust accurately.

Many regulators also have a high pressure gauge to read the amount of gas in the bottle. The high pressure gauge should be used in systems that do not have a back up bottle of CO2 so there will be enough warning to get a new bottle. Always replace the bottle once the pressure on the secondary gauge begins to drop and nears the red area of the high pressure gauge. When the primary pressure gets low in the bottle the secondary pressure will begin to drop. You will not lose very much CO2 if the bottle is changed before it is empty, and you will prevent pouring problems that waste beer.

Beer and CO2 Line

What brand to use? Any vinyl line that is brewery approved sold by a draught parts distributor is usually ok, but there are things to look for. Always get clear line for gas and beer. This will allow you to see if the line is clean and aids troubleshooting (I will cover this later). It is possible for the thomas (check, one way) valve in the tap to fail and let beer into the gas line, clear line will let you see this and fix it. Of course, clear beer line lets you see yeast and beer stone build up in the line plus it will let you actually see the gas breaking out of the beer when the pressure is set too low. Air line is usually 5/16" id and beer line is always 3/16" id (in a short system). Using 1/4" id or larger for beer line will not restrict your system properly and prevent the proper pressure adjustment. Ask for the restriction value (pressure drop) of the line when you purchase it.

There are many brands of pressure regulators. The prices vary greatly, all are basically the same. There are a few features that are important to look for.

There should be secondary a pressure gauge that reads, at most, 60 psi. Gauges that read higher than this are difficult to adjust accurately.

Many regulators also have a high pressure gauge to read the amount of gas in the bottle. The high pressure gauge should be used in systems that do not have a back up bottle of CO2 so there will be enough warning to get a new bottle. Always replace the bottle once the pressure on the secondary gauge begins to drop and nears the red area of the high pressure gauge. When the primary pressure gets low in the bottle the secondary pressure will begin to drop. You will not lose very much CO2 if the bottle is changed before it is empty, and you will prevent pouring problems that waste beer.

Beer and CO2 Line

What brand to use? Any vinyl line that is brewery approved sold by a draught parts distributor is usually ok, but there are things to look for. Always get clear line for gas and beer. This will allow you to see if the line is clean and aids troubleshooting (I will cover this later). It is possible for the thomas (check, one way) valve in the tap to fail and let beer into the gas line, clear line will let you see this and fix it. Of course, clear beer line lets you see yeast and beer stone build up in the line plus it will let you actually see the gas breaking out of the beer when the pressure is set too low. Air line is usually 5/16" id and beer line is always 3/16" id (in a short system). Using 1/4" id or larger for beer line will not restrict your system properly and prevent the proper pressure adjustment. Ask for the restriction value (pressure drop) of the line when you purchase it.

Faucets

There are three basic types of beer faucets. First, the regular ordinary faucet you will see in every bar on the planet; second, the little plastic one that hooks directly to the line; and third the euro type that is most common in dispensing Guinness.

Unless you plan on serving Guinness on tap in your home, the ordinary faucet is the best choice.

Never use the little plastic faucets for co2 dispense, they only work well on hand pumps, under low pressure, for one day parties.

If you occasionally serve Guinness or a similar product on tap at home, the euro style faucet will work on all beers if you remove the little disc from the plastic output spout. The disc has 5 tiny holes in it and serves to strip out what little co2 Guinness has, giving it the special head characteristics. Any beer carbonated over about 2.0 volumes will be all foam if poured through the disc. When dispensing a low co2 level Guinness type beer through the disc it takes a lot of extra pressure, usually 20 to 30 psi. Using pure co2 will ruin the beer at this pressure. If you dispense using the euro faucet with the disc, most breweries suggest 25% co2 / 75% nitrogen "beer gas" at 30 psi.

Faucets must be cleaned at least every two weeks. The faucet spout is exposed to air and will pick up a lot of wild yeast growth, it has to be cleaned regularly! If you have a home keg setup you must invest in a cleaning kit that comes with a faucet wrench and a faucet brush.

Perlick forward Seat Ssteel in the flow of beer.

Shanks

The shank is the threaded metal pipe that attaches to the beer line at one end and the faucet at the other. There are two things to consider when buying a shank. First is the length. If you are using an old fridge, the shank needs to extend into the fridge about 6" to help keep it and the faucet cold. The other thing to consider is the inside diameter. Always use a 1/4" id shank. This reduces the force the beer hits the back of the faucet with and reduces foam. Some more highly carbonated beers will not pour through a 3/16 shank without a LOT of foam. All beers pour better through a 1/4" shank.

Line Length and Restriction

The system restriction controls the flow rate of the beer from the faucet. Most of the restriction comes from the beer line. There is also restriction from gravity and from some draught equipment but it has little effect (less than 1 foot of length) on most short systems. (If your system has a lot of vertical rise or fall, gravity has .5 lb/ft of restriction) Using equal pressure and restriction gives a flow rate of 1 gal/min. This is usually too fast. The best way to determine the right length is to take the ideal pressure, add 5, divide by the line's restriction value per foot. If the beer pours too slow for you, shorten the line 6" at a time.

Example:

System is 38 degrees.

Distributor recommends 12 psi at 38 deg for the beer you are serving.

Parts vendor says the line has 3 lb/ft of restriction.

12 psi plus 5 (to slow) = 17

17 divided by 3 (line restriction value) = 5 ft 8 in of line

System needs 5 ft 8 in of line at 12 psi

There are three basic types of beer faucets. First, the regular ordinary faucet you will see in every bar on the planet; second, the little plastic one that hooks directly to the line; and third the euro type that is most common in dispensing Guinness.

Unless you plan on serving Guinness on tap in your home, the ordinary faucet is the best choice.

Never use the little plastic faucets for co2 dispense, they only work well on hand pumps, under low pressure, for one day parties.

If you occasionally serve Guinness or a similar product on tap at home, the euro style faucet will work on all beers if you remove the little disc from the plastic output spout. The disc has 5 tiny holes in it and serves to strip out what little co2 Guinness has, giving it the special head characteristics. Any beer carbonated over about 2.0 volumes will be all foam if poured through the disc. When dispensing a low co2 level Guinness type beer through the disc it takes a lot of extra pressure, usually 20 to 30 psi. Using pure co2 will ruin the beer at this pressure. If you dispense using the euro faucet with the disc, most breweries suggest 25% co2 / 75% nitrogen "beer gas" at 30 psi.

Faucets must be cleaned at least every two weeks. The faucet spout is exposed to air and will pick up a lot of wild yeast growth, it has to be cleaned regularly! If you have a home keg setup you must invest in a cleaning kit that comes with a faucet wrench and a faucet brush.

Perlick forward Seat Ssteel in the flow of beer.

Shanks

The shank is the threaded metal pipe that attaches to the beer line at one end and the faucet at the other. There are two things to consider when buying a shank. First is the length. If you are using an old fridge, the shank needs to extend into the fridge about 6" to help keep it and the faucet cold. The other thing to consider is the inside diameter. Always use a 1/4" id shank. This reduces the force the beer hits the back of the faucet with and reduces foam. Some more highly carbonated beers will not pour through a 3/16 shank without a LOT of foam. All beers pour better through a 1/4" shank.

Line Length and Restriction

The system restriction controls the flow rate of the beer from the faucet. Most of the restriction comes from the beer line. There is also restriction from gravity and from some draught equipment but it has little effect (less than 1 foot of length) on most short systems. (If your system has a lot of vertical rise or fall, gravity has .5 lb/ft of restriction) Using equal pressure and restriction gives a flow rate of 1 gal/min. This is usually too fast. The best way to determine the right length is to take the ideal pressure, add 5, divide by the line's restriction value per foot. If the beer pours too slow for you, shorten the line 6" at a time.

Example:

System is 38 degrees.

Distributor recommends 12 psi at 38 deg for the beer you are serving.

Parts vendor says the line has 3 lb/ft of restriction.

12 psi plus 5 (to slow) = 17

17 divided by 3 (line restriction value) = 5 ft 8 in of line

System needs 5 ft 8 in of line at 12 psi